Online shopping has been on a steady rise since 2010, with the global pandemic accelerating its adoption. Consumers quickly embraced the convenience of choosing items from home and having them delivered within days. This shift in consumer behavior is reflected in the numbers: in 2024, 20.1% of retail purchases took place online, a figure expected to surpass 30% by 2030.

This rapid growth has made AI and decision automation crucial tools for retailers to manage the complexities of omnichannel operations efficiently and stay competitive in the evolving market.

The Evolution of Retail Operations

Traditionally, many companies operated separate business units for e-commerce and brick-and-mortar stores, with distinct warehouses and fulfillment centers. Online and in-store inventories were managed separately, often leading to stockouts in e-commerce channels even when products were available in stores.

However, the retail landscape has dramatically shifted. Now, retailers compete on speed of delivery, product availability, and customer convenience. This new reality has pushed companies to leverage their entire store network to serve online customers, introducing both opportunities and challenges.

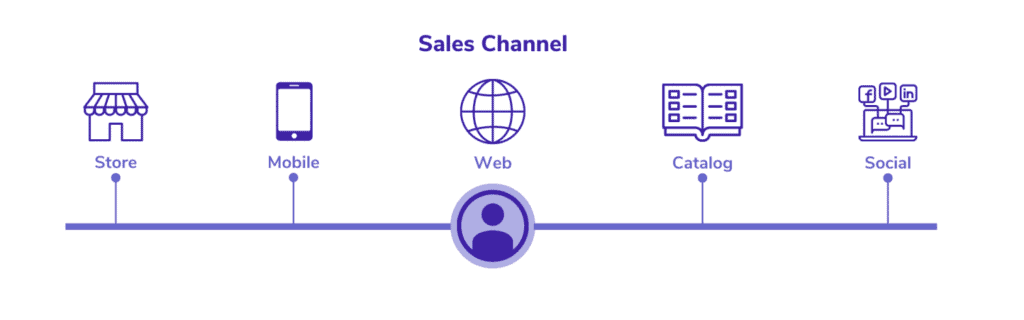

Embracing Omnichannel Capabilities

Omnichannel capabilities have become a game-changer, allowing retailers to fulfill online orders using store inventory and allowing customers to pick up or return online purchases at physical locations. While this integration requires significant IT investments and operational changes, it also presents opportunities to reduce store overstocks and markdowns.

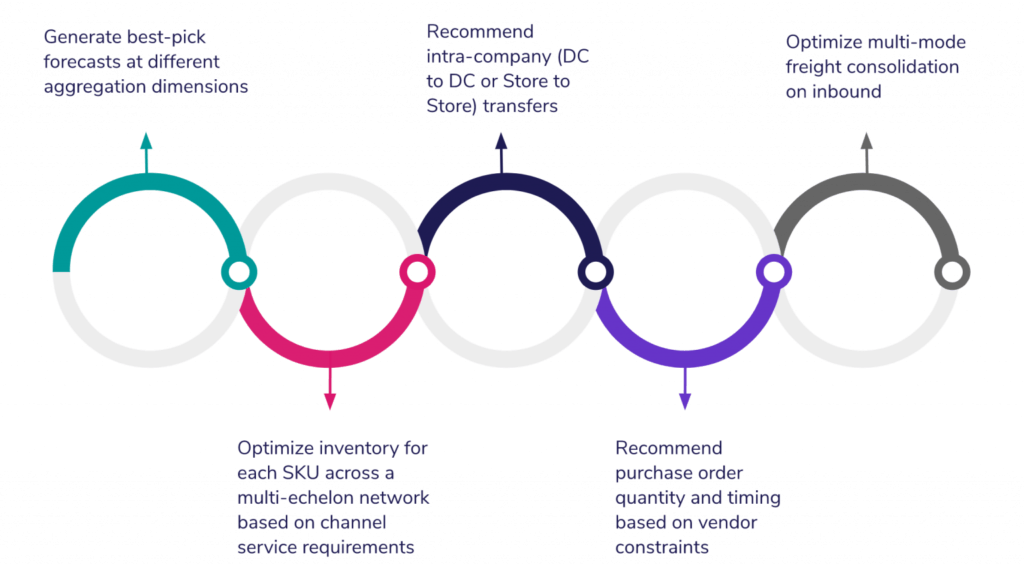

To effectively implement omnichannel fulfillment, retailers must leverage advanced analytics for strategic, tactical, and operational supply chain planning decisions. The following sections will explore key initiatives retailers should consider in their omnichannel planning efforts.

Online shopping has been on a steady rise since 2010. With the global pandemic, it became a necessity. Consumers who realized the ease of use of online shopping—choosing items from the warmth of their seats and having them delivered in a couple of days—gained a new habit.

1. Capturing sales and fulfillment data

Key considerations include fulfillment cost, selections of stores for omnichannel fulfillment, operational requirements, and customer expectations about the delivery timeline and the number of shipments. All of these factors need to be tracked and analyzed, which means the sales transactions should include a selling location (where the order comes in), fulfillment location, expected delivery date, fulfillment date, and receiving date.

AI-powered analytics can process this vast amount of data in real time, providing insights that human analysts might miss. Advanced machine learning algorithms can identify complex sales and fulfillment data patterns, leading to more accurate demand forecasting and optimized decision-making across the supply chain.

For demand forecasting and inventory optimization, order date and location are required in addition to fulfillment date and location. Unless you have visibility to demand by order location, you are likely to continue underestimating online demand, especially during stock-outs in the e-commerce warehouse.

On the other hand, if some selling locations are not fulfillment locations due to strategic and tactical decisions, the demand should be estimated in respective fulfillment locations and not selling locations. (Read this whitepaper for more details.)

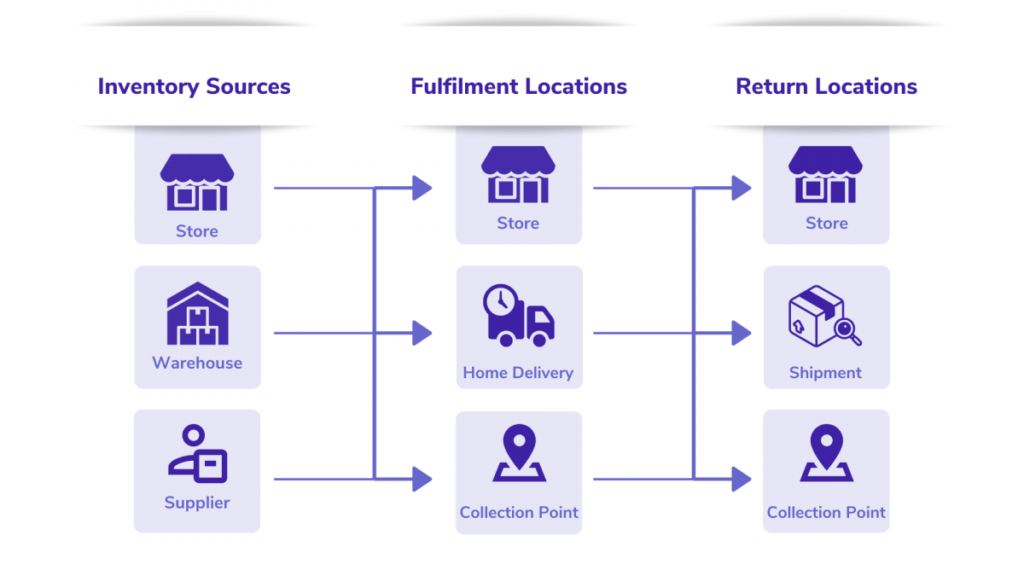

2. Incorporating returns into forecasting and inventory decisions

The return rate for online sales can be as high as 30% or even more for some categories like footwear. Most of the time, the fulfillment and return locations are different. Since returns significantly affect the store inventory levels, this factor must be considered in inventory planning.

AI can predict return rates based on various factors such as product type, customer demographics, and historical data. Automated decision-making systems can optimize inventory levels across locations by factoring in these predicted returns, ensuring that each store maintains optimal stock levels while minimizing excess inventory.

Keep in mind that different retailers have different ways of processing returns. Some choose to put them into the store stock on the same day, some go through a longer sanitization and QA process where returns will be available for sale after 24 hours, and some ship them back to the e-commerce fulfillment center. Defining such restriction rules and capturing them in the data is crucial.

Buying behavior varies across consumers. For instance, I prefer to shop around, wait for deep markdowns, and buy clothing items in bulk. It is usual for me to buy four pairs of shoes or eight pairs of pants at once. We do not have to wander around a shopping mall. The items are shipped to our home, and we try them on and eliminate the ones that my spouse doesn’t like. You can then return a pair of shoes and three pairs of pants to the store in the mall closest to your house.

When you buy four pairs of shoes and eight pairs of pants online, the retailer’s software should estimate the return quantity and location using historical data. If possible, the data should be personalized so that the inventory decisions for your favorite return store would change automatically.

3. Utilizing store transfers to have a better response time and lower costs

When a fulfillment location differs from a selling location, fulfilling orders takes time and extra cost. Some brick-and-mortar stores do not ship the products directly to customers but send them to the selling location first. The products are then shipped to customers from the selling locations.

A low volume of products can be shipped from fulfillment stores to selling locations whenever there is a demand. However, if AI-driven automatic transfers were made daily/weekly, we would benefit from the economies of scale. AI-powered inventory management systems can automatically determine optimal transfer quantities and timing between stores, reducing manual planning efforts and improving efficiency.

Thanks to intelligent, data-driven stock transfers between stores, customers will have less waiting time since selling locations will have the products in stock.

4. Optimizing omnichannel order fulfillment in batches

While many companies rely on static business rules applied when an order arrives, advanced AI algorithms can now quickly process multiple orders and optimize fulfillment decisions in real time.

These AI-driven systems consider inventory levels, shipping costs, and customer preferences to make dynamic, optimized decisions. Processing orders in batches with AI allows for superior fulfillment decisions that balance cost efficiency with customer satisfaction, adapting to changing conditions faster than traditional rule-based systems.

Instead of deciding on the fulfillment locations every time a new order comes, they can be combined, and optimization can be run “n” times a day while following the business rules. The “n” can be chosen depending on the number of orders and customer response level. Optimal transportation and multi-stop routing options will be available if the company delivers the orders.

One important consideration is minimizing the number of packages customers receive for their orders. Some customers may strongly prefer to receive a single package, so shipping all line items of an order together will go a long way toward customer satisfaction.

The other day, we ordered ten T-shirts for my wife, which all arrived in seven deliveries in five days. We ordered two of the same T-shirts, and they did not even arrive together. They probably thought this was cost-optimal, but they did not consider our disappointment. We decided not to buy anything from that retailer again. They might have lost many other customers because of their policy.

5. Taking a strategic approach to determining fulfillment locations

Instead of opening all store networks for omnichannel fulfillment, conducting an AI-powered network design analysis is crucial. The role and capacity of each location can be determined by running advanced network optimization models incorporating machine learning algorithms.

While major strategic decisions aren’t made daily, AI-powered systems can continuously analyze data and suggest adjustments to fulfillment strategies, allowing for more dynamic and responsive supply chain management. This approach enables businesses to adapt quickly to market changes, seasonal fluctuations, and unexpected disruptions.

With this work, some locations can only be selling locations to ensure optimal investments for potential fulfillment locations. That being said, the capacity for fulfillment locations could be decided on to serve offline customers better.

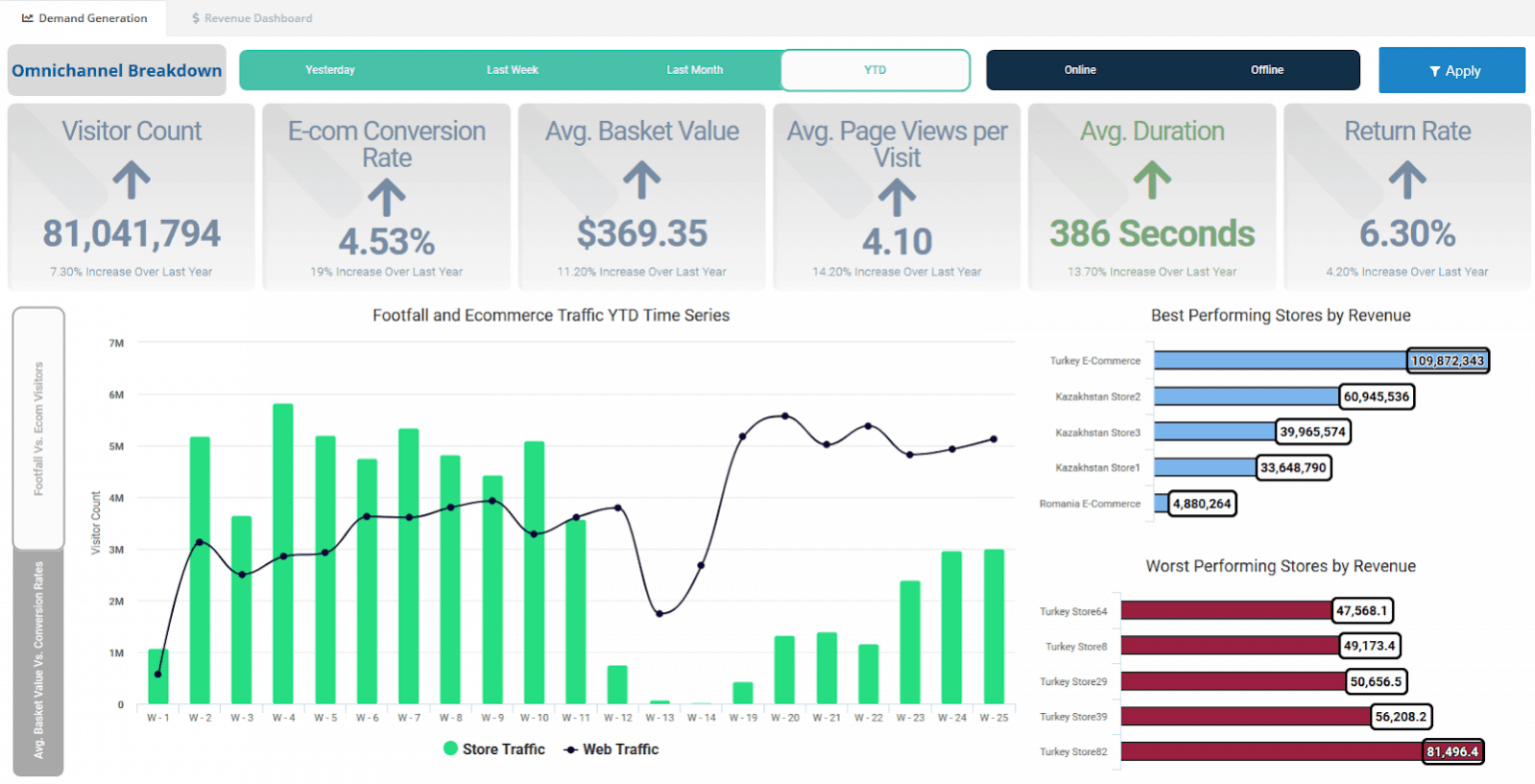

Omnichannel Planning Made Easy

We mentioned important factors retailers should consider in their omnichannel planning efforts. Business rules must be incorporated, fulfillment locations must be considered, and relevant data must be monitored for accurate predictions. All of these factors are hard to manage using spreadsheets. Most retailers transform and manage their supply chains on digital platforms like cloud-based software.

An ideal AI-powered software solution will ensure that omnichannel operations are managed according to the company’s business rules and requirements while also providing adaptive optimization capabilities. These can include the choice of fulfillment and selling locations, which will be continuously optimized throughout the year based on orders, customer responsiveness, and changing market conditions.

AI and decision automation streamline the entire omnichannel planning process, reducing human error and allowing planners to focus on strategic decisions rather than routine tasks. This leads to more efficient operations, improved customer satisfaction, and, ultimately, higher profitability.

Demand will be estimated in their respective fulfillment locations and not at their selling locations. If orders are matched one by one, this estimation can be made with business rules or the software’s optimized answer. Products can be automatically transferred between selling locations based on the prescriptive analytics provided by the software, where daily replenishments and transfers are optimized based on operational capacity.

In omnichannel planning software, all of the required data can be processed by leveraging advanced analytics and machine learning. These data will be used for predictive analytics to forecast demand and return rates. Then, prescriptive analytics will optimize the inventory level in fulfillment and selling locations.

A perfectly optimized omnichannel planning process will please families and ensure they fulfill all their needs from e-commerce retailers!