As a high school student, I worked at a deli that served breakfast and lunch during the day and ice cream at night. Motivated by how many tips I could get, I hated when it would rain for a week straight in the summer because very little ice cream would be sold, and the tip jar would stay empty. During summer days, I didn’t mind doing inventory checks in the fridge and freezer because it meant I got to cool down. However, I did have a problem with it when I had to open the liverwurst to check the date, only to find that it was expiring that week and needed to be thrown out.

Given that we are in the age of AI/ML, I often think of how the small deli where I worked was a perfect training ground for applying AI/ML in fresh supply chain planning. There are various use cases of AI/ML for demand planning of fresh products, from producers to large grocery chains and even small delis in suburban Pennsylvania. In this blog, I will discuss the use of AI/ML demand planning for fresh products to help maximize sales and reduce waste.

Data Normalization & Removing Bias

Data normalization in the context of forecasting is the process of going from actualized sales, which may be biased by various factors such as weather or inventory availability, to an understanding of baseline demand that is stripped of the impacts of these demand drivers. For instance, there was a heatwave last week, so we sold twice as much ice cream. Next week, temperatures go back to seasonal norms; what does that mean about my expected demand? Being able to do this automatically using AI saves planners so much time and hassle.

Another example of data normalization is accounting for lost sales due to stockouts or waste of perishable products due to overstocking of inventory. When I throw out a liverwurst because it has expired in the deli fridge, that waste needs to be accounted for when forecasting later in the future. Similarly, when the weather is warmer than normal, and we stock out of chocolate ice cream, that impacts both future forecasts and the replenishment plan for the following week.

New Products and Seasonal Products

New ice cream flavors are constantly being created, and without some level of insight, it is difficult to forecast the demand behavior for each new product. Often, planners spend hours trying to get to a good forecast. By looking at the different product attributes, such as base flavor, ingredients, and product name, similarity can be identified via AI/ML and leveraged to create an accurate forecast. For example, the demand for the Chocolate Peanut Butter Cup will behave much more similarly to the flavor of Chocolate than Rainbow Sherbert.

When forecasting new products, AI/ML uses attribute-based forecasting to identify similar products so that accurate forecasts can be generated for products without historical data.

When forecasting seasonal products, automatic classification and lifecycle modeling address different types of demand patterns by product. The demand for cranberry sauce during the Thanksgiving season needs to be treated much differently than the demand for vanilla ice cream in the summer months.

Automated new and seasonal product forecasting provides companies with the ability to maximize sales and reduce waste through accurate demand planning.

Real-Time What-If Planning with AI

Using what-if analysis to evaluate different scenarios by incorporating internal and external events is a key way to utilize AI/ML in demand planning.

AI models can help generate different forecast scenarios for normal temperatures and extreme hot and cold cases. As discussed earlier, the weather heavily dictates demand for certain products like ice cream. By leveraging scenario planning, we can plan for the best, worst, and most likely scenarios so that all options are considered when forecasting.

AI-driven forecasting with weather-sensitivity drivers can easily help you run through different scenarios within seconds. Today, it looks like next week’s temperatures will close to seasonal norms. However, in three days, that might change, and we can see a tropical storm coming our way. To what extent will my demand be impacted by rainy weather? Wouldn’t it be cool to know within minutes?

Given the state of ever-changing prices, we can scenario plan the sensitivity of demand based on product features and product price. For example, if a deli needs to raise its prices to meet margins for roast beef, it can accurately forecast demand based on different scenarios of the price that it sets. This includes price changes such as discounts and promotions based on historical sales and the impact on demand.

Creating demand scenarios corresponding to different factors, such as price changes or weather conditions, ensures that companies always consider all aspects of their demand planning process.

In summary, with so much to consider when it comes to demand planning for fresh and seasonal products, using AI/ML techniques will be critical for companies moving forward. While delis will not have the need or budget for some of the great tools available, their problems are the same as those of their suppliers and some of the larger grocery chains worldwide. The same challenges I was faced with as a meat slicer and ice cream scooper exist today, and as outlined in the sections above, we now have the technology to face them at all levels of the supply chain!

Tackle Fresh Retail Challenges with Solvoyo

As a retailer; the rapidly changing market can pose a significant challenge to your supply chain planning.

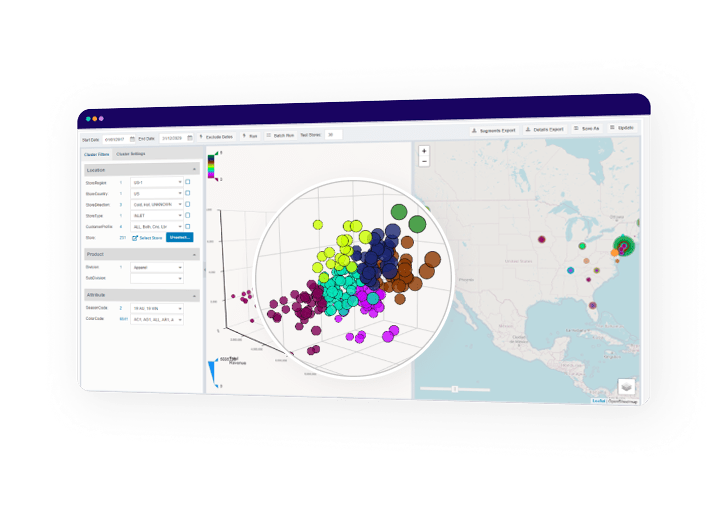

Solvoyo’s advanced analytics and machine learning capabilities have enabled fresh grocery retailers to sense demand changes, optimize inventory levels, minimize total cost to serve and collaborate with external partners.

With Solvoyo’s autonomous planning capabilities, you can manage your supply chains more effectively in light of uncertainty, avoid stock-outs, lower costs, and keep your customers happy while supporting a more sustainable business model.

Learn more about Solvoyo Digital Platform.