Demand-driven Replenishment, DC Purchasing

A101 – World’s 5th Fastest-Growing Retailer

A101 achieved digital transformation of manual planning process through a single platform supporting collaboration and visibility

Store replenishment is one of the core operational processes for retailers. The trade-off between availability and excess stock is one of the main daily challenges the planning teams face. Companies need to expect what, when, and how much customers will purchase at each channel and location and replenish accordingly to prevent lost sales, stock-outs, and customer disappointments. Especially for retailers managing large SKUs, determining each sales location’s optimal inventory targets can be challenging and time-consuming. An automated and demand-driven replenishment planning solution that tracks inventory forecasts store demand provides executable SKU level replenishment recommendations subject to operational constraints, improves availability, and minimizes lost sales.

Solvoyo Store Replenishment helps automate dynamic inventory target setting and daily replenishment decisions using demand-driven models and minimizing the possibility of lost sales. Solvoyo Demand Forecasting considers different demand drivers such as weather conditions, special events for a more accurate view of expected demand. Prescriptive analytics working with operational and business constraints such as packing requirements, store capacity, and replenishment frequency give recommendations that can be executed immediately without manual intervention. Through automated diagnostics and KPI tracking, users can quickly focus on items requiring attention, approve actions, and send work orders directly to the WMS systems.

"Using demand-driven replenishment planning gave us the agility and scalability we needed in times of market disruptions. We replaced our manual methods with automated recommendations for 10,000 stores in different locations. Thanks to Solvoyo’s daily replenishment recommendations, we gained a competitive edge by reducing stock-outs and increasing availability."

Inventory Optimization working with store/DC capacity, store replenishment frequencies and other operational considerations

Load-balancing for DC work orders

Integrated with warehouse PO management for fewer manual interventions

Automatic selection from 30+ forecasting methods for best fit, including promotion effect and pricing options

Improve inventory productivity and reduce lost sales

SKU/Store forecasting leveraging machine learning taking into account demand-drivers such as promotions, special dates, and weather changes ensures a more accurate version of the expected demand

DC Replenishment integrated with Store Replenishment ensures DC-purchase orders always consider store needs

Integration with ERP system enables automated PO creation with faster execution

Demand-driven inventory optimization of competing goals – inventory cost and lost sales

Highly and quickly scalable and adaptable for business growth, supporting new categories, new channels, and new store locations

Short implementation cycles of cloud-native single planning platform

Solvoyo Cognitive Learning for new product introduction and store openings

Single data model and analytics engine for end-to-end SC platform all easily accessible through a configurable user interface

A101 – World’s 5th Fastest-Growing Retailer

A101 achieved digital transformation of manual planning process through a single platform supporting collaboration and visibility

DeFacto – Multinational Apparel Retailer

DeFacto reached a 100% automated initial allocation & replenishment processes’ accepting 90% of 150+ weekly recommendations

Penti – Apparel Retailer

With smarter replenishment decisions, Penti balanced inventory across the chain enabled 25% revenue growth with only 2% increase in stock

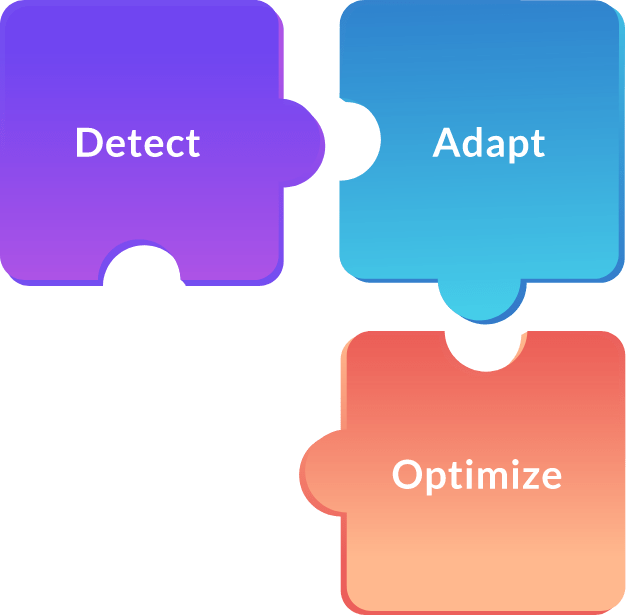

Detect the recent demand pattern and response to special events and promotions

Detect the recent demand pattern and response to special events and promotions

Safety stock targets based on demand-drivers like promotions, special days and weather into account

Provide optimal replenishment quantities to minimize lost sales and prevent excess stock

Safety stock targets based on demand-drivers like promotions, special days and weather into account

Provide optimal replenishment quantities to minimize lost sales and prevent excess stock

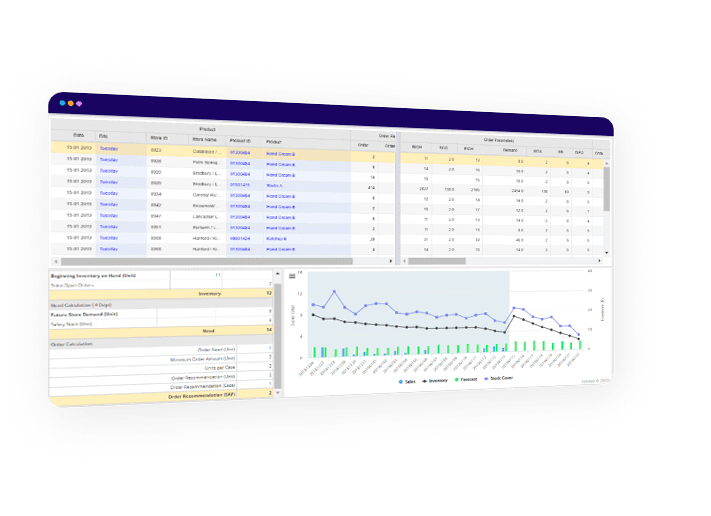

Daily SKU specific replenishment recommendations based on demand forecast and operational constraints

Planned promotions, price changes and special days are taken into account to provide a more accurate view of the demand and inventory projections

Specify triggers for automated PO review & approval, exception management and automated decision filters

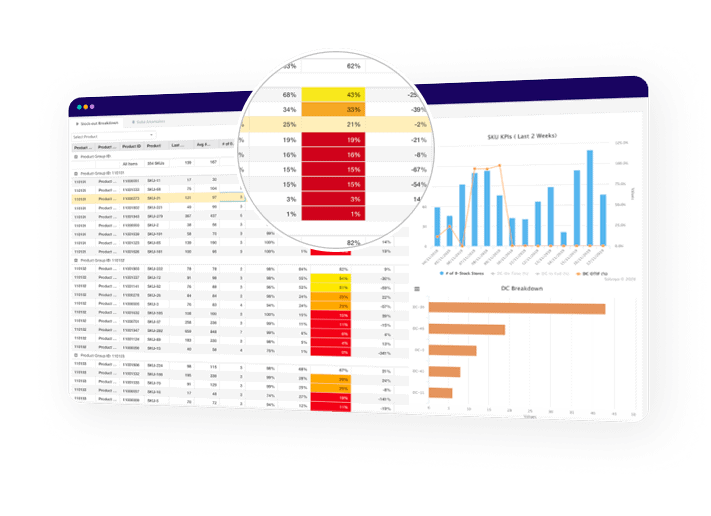

Automated diagnostics, users can quickly focus on items requiring attention such as root cause analysis for stock-outs

All relevant information on one single page; including vendor and DC performance, inventory and approval rates

Historical view of SKU specific KPIs and DC breakdown of zero-stock stores

Root cause analysis for stock-out and excess stock management

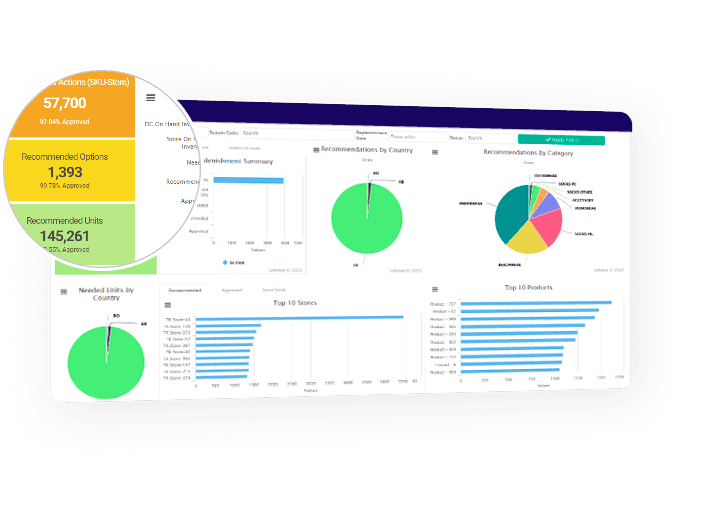

Summary dashboard allows users to monitor recommendations based on different locations and product categories

Easily track the status of recommendations and get drilled down information like inventory, buyer group, season, and forecast

Predictive Analytics with AI/ML for SKU/Store forecasts using seasonality and key product & store attributes

Prescriptive Analytics with automated replenishment recommendations

Solvoyo Cognitive Learning for new product introduction and store openings

Integrated with warehouse management systems for no-touch execution

Automated diagnostics and exception management for SKUs needing attention

Root cause analysis for stock-out and excess stock management

Subscribe to our newsletter to keep up with what’s next in retail planning.

77 Franklin Street

Boston, MA 02110

+1 617 642 1338

Istanbul Technical University

ARI2 Teknokent

B1-3, 34467

Maslak, Istanbul

+90 212 286 6061

–

Kolektif House 1071 Ankara

Çankaya, Ankara

–

Logothetidi 34, 11524

Attiki, Athens