End-to-End Autonomous Planning & Analytics

Unilever – Fortune 100 Global CPG

Managing all their supply chain planning data on a single platform, they achieved real-time visibility & agility for faster decision-making

Solvoyo Supply Chain Analytics & Visibility empowers you to lead, not follow. Our advanced machine-learning algorithms allow you to quickly evaluate multiple what-if scenarios and delve into complex supply chain challenges. While competitors are bogged down in planning, your team can reduce manual tasks and accelerate response times with our automated diagnostics. Focus on strategic issues and derive actionable insights from vast amounts of data.

Supply chain analytics, at its essence, is about transforming big data from multiple internal and external sources into insights for making better planning decisions. Solvoyo uses advanced analytics and machine learning to data from internal and external sources as well as IoT to integrate descriptive, diagnostic, predictive, and prescriptive capabilities to empower supply chain managers to make better supply chain decisions.

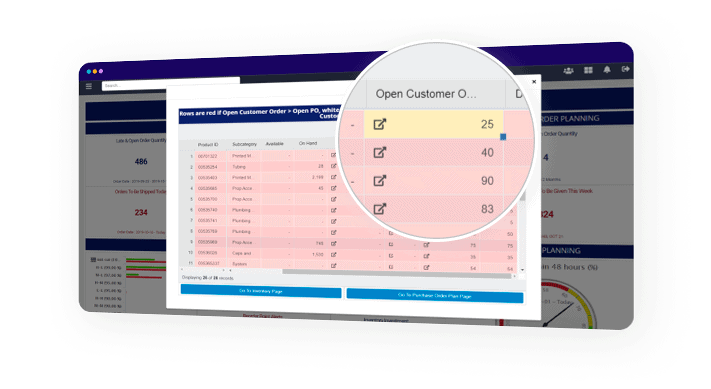

The backbone of Solvoyo platform is its cutting-edge AI capabilities, which automate the diagnostics of supply chain operations. This system identifies key issues in real time, from stock-outs to service level discrepancies, by analyzing patterns and trends through machine learning. This allows planners to focus swiftly on critical areas, enhancing responsiveness and reducing downtime.

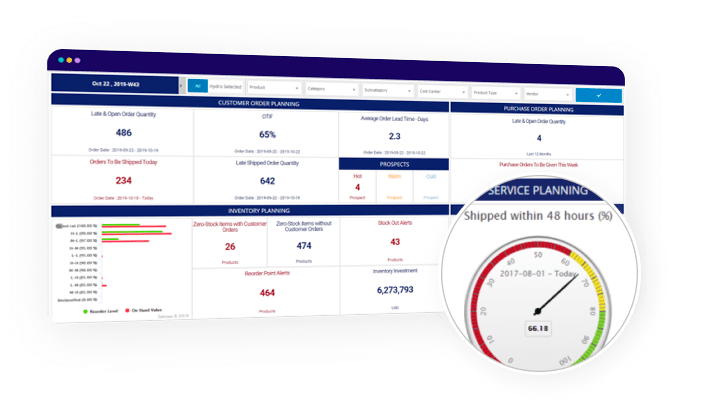

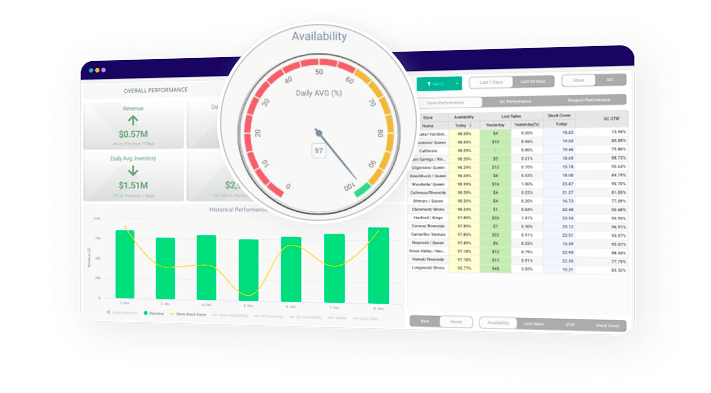

Achieve unparalleled transparency with Solvoyo’s Control Tower, which offers a comprehensive view of your end-to-end supply chain. From real-time tracking of in-transit inventory to analysis of demand variability and forecast bias, the platform ensures that every facet of your supply chain is visible and under control. This enhanced visibility aids in pinpointing efficiency bottlenecks and optimizing overall supply chain performance.

Solvoyo’s advanced cross-functional KPI dashboard integrates seamlessly into the Control Tower, providing a visual cockpit for monitoring and analyzing performance metrics. It includes sophisticated AI tools that track and learn from every transaction, continuously improving data accuracy and process efficacy through self-learning algorithms. This automation extends to identifying root causes of performance deviations, enabling faster resolution and strategic adjustments.

Supply chain analytics, at its essence, is about transforming big data from multiple internal and external sources into insights for making better planning decisions. Solvoyo uses advanced analytics and machine learning to data from internal and external sources as well as IoT to integrate descriptive, diagnostic, predictive, and prescriptive capabilities to empower supply chain managers to make better supply chain decisions.

The backbone of Solvoyo platform is its cutting-edge AI capabilities, which automate the diagnostics of supply chain operations. This system identifies key issues in real time, from stock-outs to service level discrepancies, by analyzing patterns and trends through machine learning. This allows planners to focus swiftly on critical areas, enhancing responsiveness and reducing downtime.

Achieve unparalleled transparency with Solvoyo’s Control Tower, which offers a comprehensive view of your end-to-end supply chain. From real-time tracking of in-transit inventory to analysis of demand variability and forecast bias, the platform ensures that every facet of your supply chain is visible and under control. This enhanced visibility aids in pinpointing efficiency bottlenecks and optimizing overall supply chain performance.

Solvoyo’s advanced cross-functional KPI dashboard integrates seamlessly into the Control Tower, providing a visual cockpit for monitoring and analyzing performance metrics. It includes sophisticated AI tools that track and learn from every transaction, continuously improving data accuracy and process efficacy through self-learning algorithms. This automation extends to identifying root causes of performance deviations, enabling faster resolution and strategic adjustments.

Unilever – Fortune 100 Global CPG

Managing all their supply chain planning data on a single platform, they achieved real-time visibility & agility for faster decision-making

P&G – Fortune 100 Global CPG

The Global CPG company uses a single digital platform to maintain global demand, inventory and supply visibility

Hepsiburada – E-Commerce Retailer

Hepsiburada automated their approach to detect slow moving inventory and optimize price actions to meet budget targets

Monitor key performance indicators and manage exceptions with our analytics dashboard, designed to track metrics like stock coverage, lost sales, and fulfillment rates, providing a solid foundation for your analytics efforts.

Automated diagnostics identify the root causes of issues like stock-outs or service level declines. By pinpointing problems related to demand variability, forecast bias, and supplier performance, Solvoyo enables planners to focus on solutions.

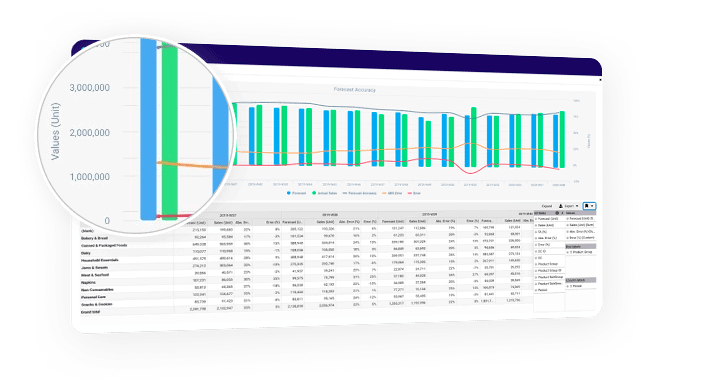

Employ AI-driven forecasting techniques that use event libraries and external data to predict and mitigate potential stock-outs lost sales, and over-stock situations. Solvoyo’s what-if capabilities allow planners to assess various scenarios and make proactive decisions.

Gain insights into key supply chain metrics, such as product availability, lost sales, and supplier performance, presented in a user-friendly visual format to facilitate quick decision-making

Solvoyo provides insights into locations and products with high forecast errors, enabling targeted interventions to enhance accuracy and reduce impacts on operations.

Solvoyo analytics platform provides lost sales estimations in case of out-of-stock situations. You can quickly review the locations and products and compare them to recent trends.

Subscribe to our newsletter to keep up with what’s next in retail planning.

77 Franklin Street

Boston, MA 02110

+1 617 642 1338

Istanbul Technical University

ARI2 Teknokent

B1-3, 34467

Maslak, Istanbul

+90 212 286 6061

–

Kolektif House 1071 Ankara

Çankaya, Ankara

–

Logothetidi 34, 11524

Attiki, Athens